Piston Ring Types - Compression Ring

There are many types of piston ring: rectangular, taper faced, internally bevelled or stepped, keystone, half keystone and L-shaped compression ring – here we focus on the compression ring, its uses and variations.

A piston ring is a metallic ring used to seal the chamber in a combustion engine in order to maintain gas compression between the piston and cylinder wall, and assuring the flow of heat from the piston to the cylinder.

The most commonly used piston rings include the compression ring used for sealing the chamber, and oil control ring (also known as the scrapper ring) used to control the supply of oil to the cylinder wall.

Compression Ring Types

Rectangular Piston Ring:

The rectangular piston ring has a geometrically simple shape and provides the sealing functions under normal operating conditions. The rectangular ring has a peripheral coating and is used in internal combustion engines and as rotary shaft seals, e.g. transmission seals.

Taper Faced Piston Ring:

The taper faced ring connects the cylinder bore with its bottom outer edge. The taper shortens running-in and improves oil scraping. The gas forces acting initially at the running face provide a degree of pressure relief. Taper faced rings often used in the second groove in car and truck engines, but can also be used in the top groove.

Internally Bevelled or Stepped Piston Ring:

Creating an edge relief on the top side of rectangular and taper faced rings results in a twisting effect which, without gas pressure loading, brings the ring into bore contact only with its bottom outer edge while the inner edge contacts the bottom groove side. The twist effect helps to improve oil consumption control. In use the gas pressure forces the ring flat against the piston groove, this creates an additional dynamic behaviour of the ring. Internally bevelled or stepped rings are used in the top and second groove of petrol cars and truck diesel engines.

Taper Faced Piston Ring with Inside Bottom Bevel or Step:

Internally bevelled or stepped rings are used in the top and second groove of the piston. Installed the edge relief on the top side of rectangular and taper faced rings results in a twisting effect brings the ring into bore contact only with its bottom outer edge while the inner edge contacts the bottom groove side.

Keystone Piston Ring:

The keystone ring is used in the top groove of a piston. It is a compression ring with a wedge cross section. Its tapered sides create a running surface allowing radial movement of the ring in the grooves during engine operation which cause the axial clearance in the groove to increase and decrease reducing sticking.

Half Keystone Piston Ring:

The half keystone piston ring is a compression ring with the top side tapered. Like the keystone piston ring its tapered edge allows radial movement of the ring reducing sticking.

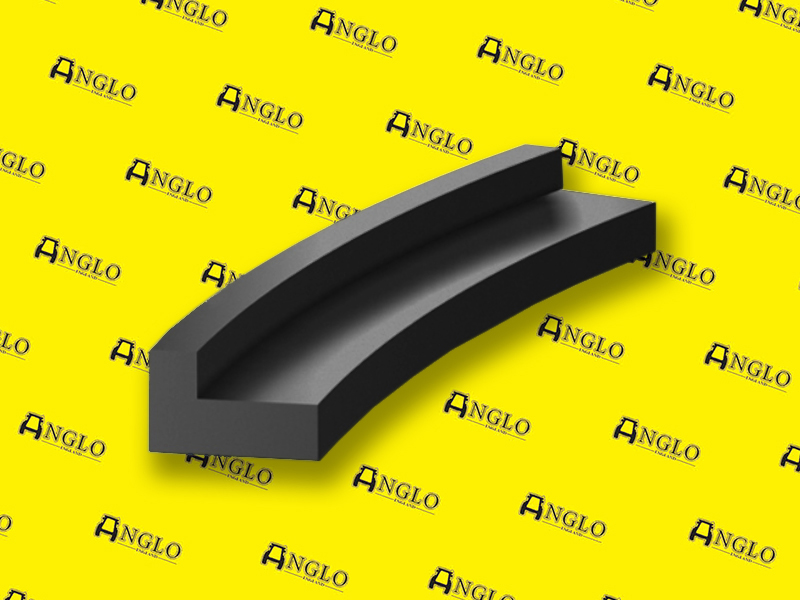

L-Shaped Compression Ring:

The L shaped ring vertical arm is designed to be flush with the top edge of the piston crown – creating a seal when it comes into contact with the top side of the piston groove and is often used in 2-stroke engines

Licence Terms

You are free to: Share, copy & redistribute the material in original format for any purpose as long as you follow the license terms below:

- Attribution – you must give appropriate credit and provide a link to the original article in a reasonable and visible manner

- You may not in any way suggest that the licensor endorses you or your use.

- No Derivatives – The material must be distributed in full, including disclaimer, you may not distribute or share modified material.

- No additional restrictions – You may not apply legal terms that legally restrict others from doing anything the licence permits.

- No warranties are given. The license may not give you all of the permissions necessary for your intended use. For example other rights such as publicity, privacy, or moral rights may limit how you use the material.

Disclaimer

Related Articles

Piston Ring Types - Scraper Ring

Scraper rings are designed with a step recessed into the bottom outface and scrap the oil off the cylinder walls, prevent its entrance into the combustion chamber and send back it to the crankcase. Here we provide an overview on the different scraper rings.

Piston Ring Types - Oil Control Ring

Oil control rings are located in the bottom piston groove and their function is to control the supply of oil to cylinder wall to lubricate the piston skirt.

Ferguson TED20 - Installing The Pistons - Video Tutorial

Progress is being made! - In their latest video Gordon & Oscar install the pistons - the beating heart of an engine. Combined with piston rings they perform the crucial task of creating an airtight seal between the combustion chamber and the crankcase. The pressure allows the piston to move up and down within the hollow cylinder of the engine block.