Tractor Steering Evaluation

Steering Inspection

Having seen internet posts where people are asking how to adjust tyre pressures to stop shimmying on road runs and prettily painted tractors at shows that would be unsafe to drive at speed, it seems that many people don’t know how to inspect steering and identify problems. Some issues can be very easy to fix while the more complex will be the subject of another article.

This description uses IH Bradford built tractors (B275, B414 and B434) as examples but most of the steps will apply to any tractor.

As this whole process can take less than a couple of minutes, it is also very useful when looking at a potential purchase.

Part Indentification

To avoid confusion over names, the following pictures identify various components mentioned in the later steps.

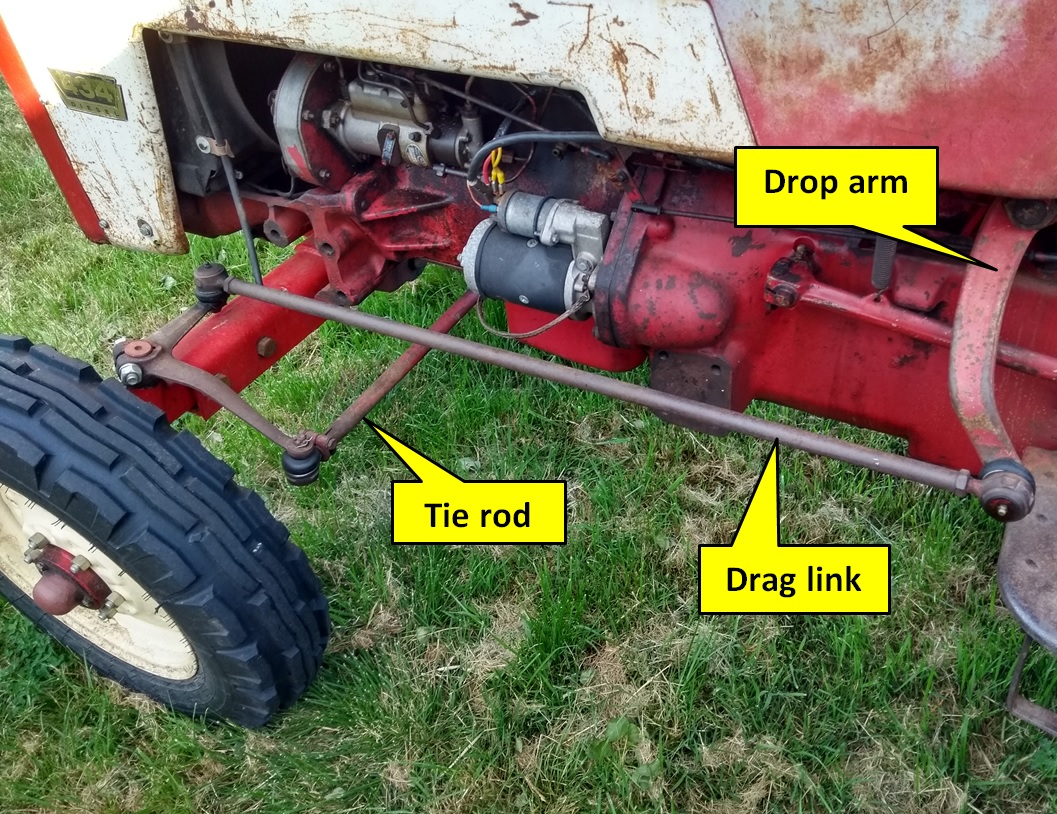

Figure 1 IH 434 steering arms

The tie rod and drag link have four swivel joints in total and, in the design engineers’ effort to minimise the number of different spares needed (joking), no two are the same!

Both tie rod and drag link can be reversed end for end so be sure to identify the correct part before ordering spares.

The tie rod has an extended swivel joint with notches at one end – when the axle extensions are moved in and out to adjust the track, the notches allow the tie rod to be easily adjusted in equal amounts without impacting on the tracking. The swivel joint at the other end is threaded and adjusted to set the tracking.

The drag link has both left and right hand threaded swivel joints. When adjusting its length to ensure that the steering “straight ahead” position matches the wheels when straight, the lock nuts are released and the drag link simply turned in the same manner as the 3-point top link.

Early swivel joints have grease nipples and replacement gaiters are available. The later swivel joints are sealed for life and don’t seem to have replacement gaiters so always take care whenever the joints are removed.

Anglo Agriparts list all four swivel joints with the later parts being direct replacements for the earlier versions.

ANGLO REF | DESCRIPTION | OEM NUMBER | ||

B275 | B414 | 434 | ||

Drag link steering joint, left hand thread | 3040921R91 | 3040921R91 | 3071055R91 | |

Drag link steering joint, right hand thread | 3040922R91 | 3040922R92 | 3071056R91 | |

Tie rod steering joint, without extension | 3040920R91 | 3040920R92 | 3071097R91 | |

Tie rod steering joint, with extension | 3040919R91 | 3040919R92 | 3071096R91 | |

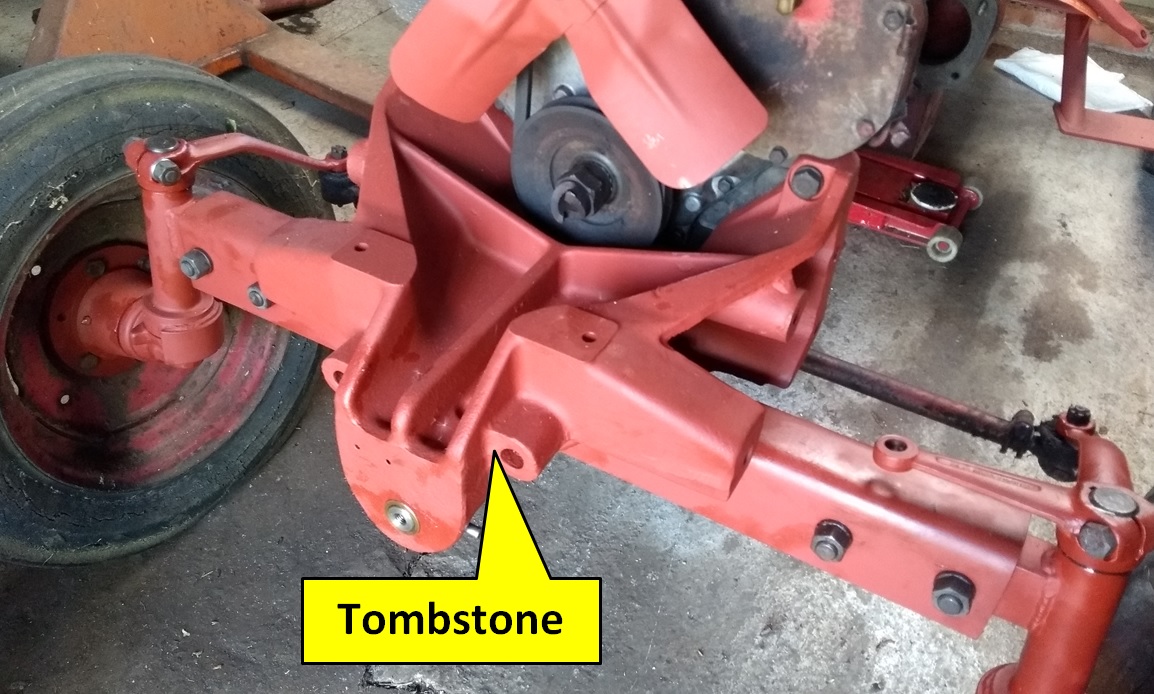

Figure 2 Tombstone or front axle support casting

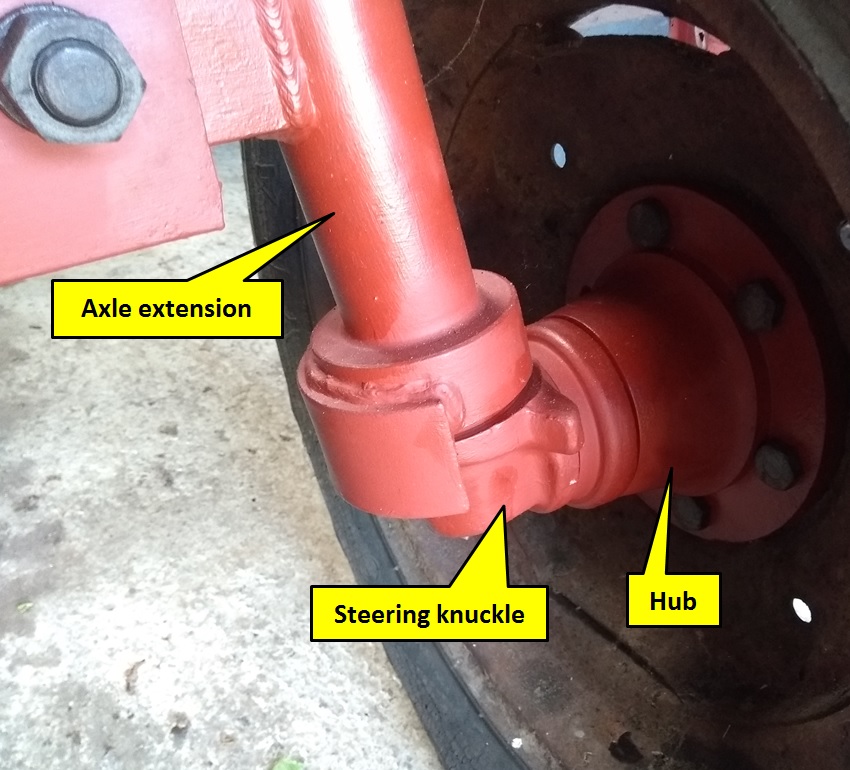

Figure 3 Front wheel, hub, steering knuckle and axle extension

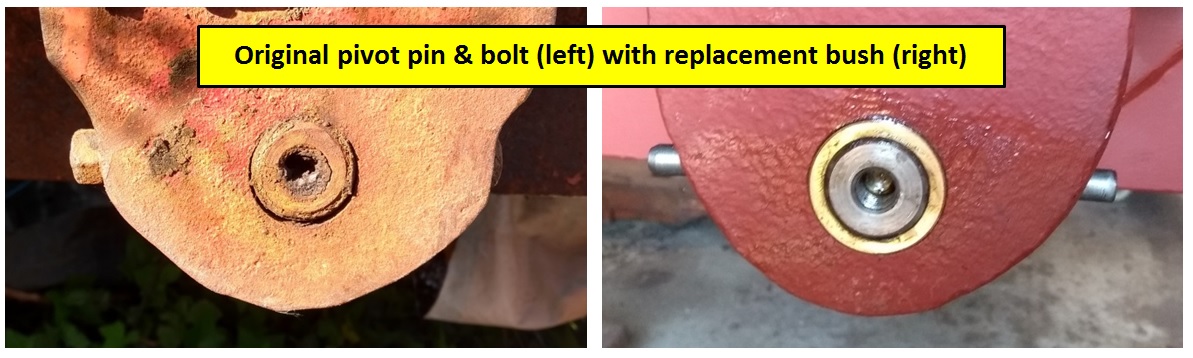

Figure 4 Two B414 front axle pivot pins

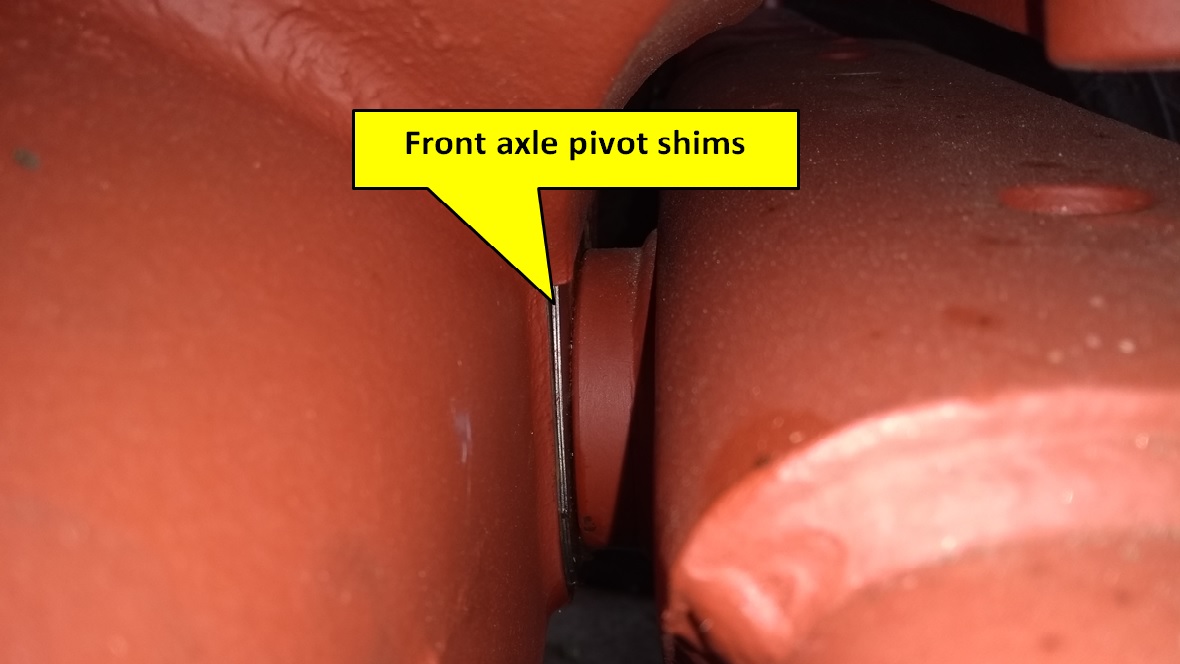

Figure 5 Front axle (right), shims and tombstone (left)

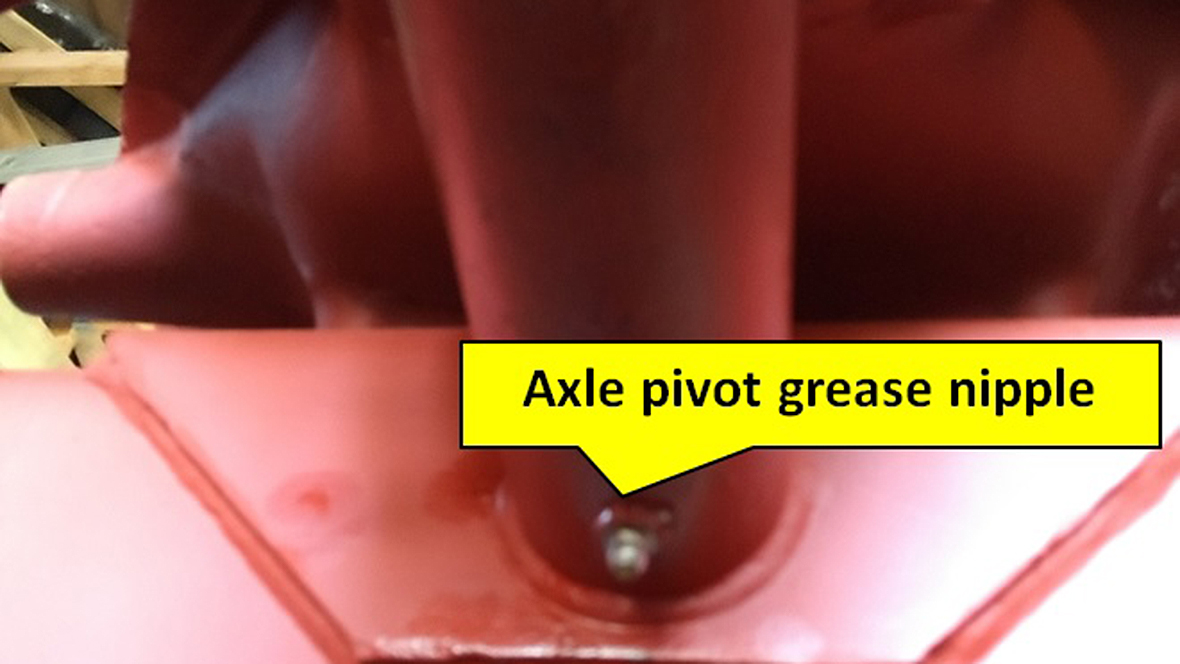

Figure 6 Underside of front axle showing the important grease nipple

Step By Step

With the tractor on its wheels and while sitting in the

driving seat the following steps move from the steering wheel to the front

wheels checking each potential problem area.

1.

Grip the steering wheel and try to rock it from

side to side and fore and aft.

a.

Is the fixing nut loose? If so, tighten it! Or replace with Anglo ref: A56749 which fits B434 if replacing with an

earlier style steering wheel.

b.

Is there play between the steering wheel shaft

and column? If so the top bush needs changing. On the IH tractors (post B250) just take the wheel off (don’t lose the woodruff key), lever out

the old bush and fit Anglo ref: A68063.

c.

Does the whole steering column move? The most

likely cause is that the steering box mounting bolts are loose.

2.

While watching the drop arm, gently rotate the

steering wheel from side to side to see how far it will turn before the arm

moves. This is an indication of the wear in the steering pin and worm inside

the steering box. On a perfect tractor there is no movement but a badly worn

steering box could have ¼ to ½ a turn of play. Fixing this isn’t a 5-minute job

so will be covered in another article.

3.

Using a little more force, turn the wheel so the

drop arm moves.

a.

Does the shaft move in and out? The early B275

steering boxes had no adjustment but later tractors have an adjustable end

thrust on the opposite side of the steering box – simply slacken the lock nut,

take up the slack on the adjusting screw and tighten the nut then repeat test 2.

b.

Does the shaft move up and down? The steering

box bush is worn and needs replacing as part of a steering box overhaul.

c.

Is oil leaking from the steering box (or is

there any oil in the box?) If so the seal will need changing, again a more

major task.

d.

Is the drop arm loose on the shaft? Tightening

the nut is the obvious first step here but if the tractor has been used a lot

with it loose then the drop arm and/or steering box rocker shaft may be worn

and need replacing… which probably means contacting a breaker.

4.

Again while moving the steering wheel to and

fro, watch the drag link where connected to the drop arm. If there is any

movement, check that the nut is tight and if it is, the joint needs replacing.

5.

Repeat the process while watching the joint at

the other end of the drag link.

6.

Repeat the process while watching the joint on

the joints at both ends of the tie rod.

7.

Using more force, turn the steering wheel to and

fro hard enough to move the front wheels while watching the front axle. If the

axle moves then there is wear in the axle bushes and/or thrust washers. This

will also be covered in another article.

8.

Get off the tractor and with each front wheel in

turn, try to rock the wheel sideways (i.e. towards and away from the nosecone)

and look for any movement between hub and front axle extension. Also check that

the extension doesn’t move in the main axle – if it does then the fixing bolts

should be tightened to 250->280 ft lb for the square axle tractors, there

doesn’t seem to be a figure for the round axle tractors. If the bolts are tight

and there is still play, the hub and steering knuckle need overhauling – again

to be covered in another article.

9.

Next look under the centre of the axle – there

should be a grease nipple (see Figure 6), but sometimes this falls out or is

broken off. THIS IS ARGUABLY THE MOST

IMPORTANT GREASE NIPPLE ON THE TRACTOR but is regularly ignored with costly

consequences as the pivot pin can seize in the bushes, shear the locating

pin/bolt and wear the tombstone.

10.

Finally look under the front of the nosecone for

where the front axle pivot pin fits into the tombstone. The pivot pin is held in

place by a tapered pin (early tractors) or a long bolt which should be present

and tight in the casting. If the securing pin/bolt is sheered then the pivot

pin is almost certainly seized in its bushes due to lack of lubrication and the

tombstone holes will have worn oversize and need machining, not a trivial job.

A final check would be to jack up the front of the tractor

and check the wheel bearing for smoothness of running and possibly a more

detailed diagnosis of bearing and steering knuckle wear.

The 434 in the first picture has had all the issues

described here fixed and there is no discernible steering play, just as it left

the factory. It is very popular for road runs.

ARTICLE CONTRIBUTED BY ANDREW CHAPMAN

© ANDREW CHAPMAN & ANGLO AGRIPARTS LTD

Licence Terms

You are free to: Share, copy & redistribute the material in original format for any purpose as long as you follow the license terms below:

- Attribution – you must give appropriate credit and provide a link to the original article in a reasonable and visible manner

- You may not in any way suggest that the licensor endorses you or your use.

- No Derivatives – The material must be distributed in full, including disclaimer, you may not distribute or share modified material.

- No additional restrictions – You may not apply legal terms that legally restrict others from doing anything the licence permits.

- No warranties are given. The license may not give you all of the permissions necessary for you intended use. For example other rights such as publicity, privacy, or moral rights may limit how you use the material.

Disclaimer

Related Articles

Tractor Steering Overhaul Part 1

Contributor Andrew Chapman compares the various methods for splitting swivel joints on steering overhauls.

Tractor Steering Overhaul Part 2

Part 2 of Andrew Chapman's steering overhaul review. This article is based on rebuilding the steering knuckles and hubs on Bradford built International Harvester B275, B414 and 434 tractors.

Tractor Steering Overhaul Part 3

This

article is based on rebuilding the front axle pivot pin and bushes on Bradford

built International Harvester B275, B414 and 434 tractors. The design of the

parts are however similar to those on many tractors of the period and so should

be of general use

Tractor Steering Overhaul Part 4

The final article in the 'Steering Overhaul' series by contributor Andrew Chapman. This article focuses primarily on steering boxes fitted to Bradford built International Harvester tractors.

Ferguson TED20 - Removing The Steering Box - Video Tutorial

The steering box contains the gears that transmit the driver's steering movements to the steering linkage that turns the wheels. In this video Gordon investigates steering issues on his TED20 - part 1 follows the step-by-step removal of the steering box.

Ferguson TED20 - Assembling Steering Box - Video Tutorial

Watch Gordon's latest installment in his video series restoring a Ferguson TED20.

Related Products

Tags steering, tractor, restoration, maintenance