Diagnosing Smoking Engines

When you have a smoking engine it is important to identify the cause to prevent long term damage. In his latest article Andrew investigates the potential causes to help you diagnose a smoking engine.

Diagnosing Smoking Engines

This diagnosis is specific to diesel engines. While there are similarities with petrol engines, diesels have their own unique problems.

While a smoking engine can have many different causes with several existing on the same worn engine, some of which can only be confirmed by internal investigation, there are a number of steps that can be taken to home in on the likely cause(s).

Are There Any Other Problems?

Sometimes smoke is only one of several problems with the engine.

- Is the engine difficult to start? Possibly low compression, faulty glowplugs or even valves not seating correctly (check tappet clearances.)

- Is it loosing water? If so and the radiator and hoses are ok it could be a blown head gasket or a porous liner.

- Is there oil in the water? Blown head gasket – fix as a matter of urgency.

- Is there water in the oil? Blown head gasket or porous liner – fix as a matter of urgency.

- Are there signs of smoke and/or oil coming out of the rocker box breather? If so, this tends to be an indication of worn or glazed bores.

What Colour is the Smoke?

Smoke would normally be in one of the following three colours although a warn engine could demonstrate all three at different times.

BLACK

Black smoke is part burnt fuel, typically seen with engines under very heavy load. For classic and vintage tractors with purely mechanical fuel injection there will always be some black smoke under heavy load so one needs to compare the engine with similar ones under equivalent conditions (e.g. on a road run or ploughing match.) Excess black smoke could be down to one or more of the following:

- Blocked or dirty air filter. If the engine is short of air to burn all the fuel, it will be ok at lower power levels but smoke when pushed hard. Clean the filter!

- Worn fuel injectors. Correctly working fuel injectors will atomise the fuel and allow a uniform burn in the cylinder. If the injector is worn then instead of an atomised spray it can be creating larger drops or even a stream of liquid which will only partially burn in the cylinder requiring more fuel (the governor will automatically increase the fuel) – the exhaust gasses will therefore be sooty. The injectors will need to be assessed and possibly reconditioned.

- Worn or incorrectly adjusted injector pump. This is a job for the specialists but probably the least likely of the causes – check and fix the other possible causes first.

WHITE

White smoke (not steam as seen from a cold petrol exhaust) is normally an indication that the fuel didn’t actually start to burn in the cylinder. This smoke will normally have a strong smell of diesel.

The two most common causes of white smoke are faulty glowplugs or low compression:

Faulty Glowplug

On tractors like the Bradford built IH B series tractors a fault in any of the series connected glowplugs or the dash indicator will stop ALL glowplugs working and the engine will be difficult or even impossible to start but will tend to produce clouds of white smoke.

On other tractors with parallel connected glowplugs it is possible to have one cylinder’s heater faulty allowing the tractor to start (with difficulty), low power and lots of white smoke until self-heating allows combustion to start in the final cylinder. The engine will then run normally.

Low Compression

Diesel engines use compression ignition – there must be enough compression to raise the temperature of the air/fuel mix (sometimes with the help of glowplugs) to the point where it will start to burn.

If the compression is very low then there may never be any combustion in a cylinder so just producing white smoke.

If the compression is moderately low on a cylinder then there will be no combustion until the engine has warmed up. This will show as difficult starting with lots of white smoke including when initially started, but runs much better when warmed up. The difference between this and a faulty glowplug is that with a faulty glowplug once a cylinder starts to fire it continues to do so with the smoke effectively just switching off while low compression will take time before the smoke stops or reduces. Sometimes the smoke will be present at lower engine speeds as there is more time for gasses to leak past the piston rings but stop at higher speeds.

BLUE

So called “blue” smoke is actually white with a bluish tint, sometimes with an oily rather than diesel smell.

If this occurs only for a couple of seconds on starting then it is probably due to worn valve seals or guides where oil runs down the valve stem when the engine is stopped but is burnt off when the engine first starts.

Blue smoke when the engine is running normally is usually due to a glazed bore (compression and starting are often ok), a worn bore or broken/stuck rings.

Glazed bores are normally a consequence of only running the engine on light duties. In mild cases this will sometimes improve with heavy work (e.g. ploughing or flail mowing) but the bore will often need honing.

Compression Testing

Test Equipment

A diesel compression tester is relatively cheap – at the time of writing they are available from about £25 via the internet.

This one that I’ve used for a number of years as it includes a M18x1.5 adapter that fits the glowplug holes on my IH B275 and 434 engines.

Testing an engine fitted with glowplugs is relatively easy as the cheap testers screw in place of the glowplug. Non-glowplug engines may need slightly different testers which will replace the injectors so ensure that you buy the correct type.

This is another example of a compression tester available online. It unfortunately doesn’t include the M18x1.5 adapter but could provide a solution for other engines

How To Compression Test

When compression testing, always ensure that the engine stop is pulled out to cut off fuel – one doesn’t want to flood the bores with unburnt fuel.

To complete testing you will need:

- A compression tester with an adapter that will fit either the glowplug (first choice if one used) or the injector. All glowplugs or injectors as appropriate should be removed to allow the engine to rotate at maximum speed on the starter.

- A good battery – one wants the engine to rotate at close to the same speed across several tests.

- Knowledge of what a “good” compression figure is.

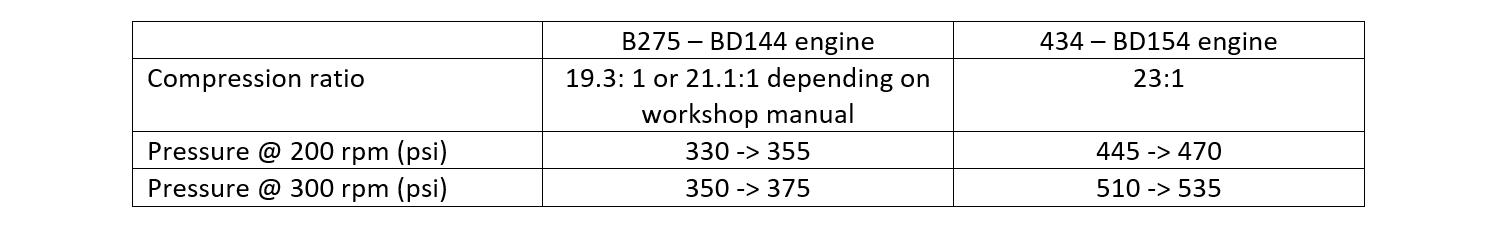

Getting the compression figure isn’t always that easy. A workshop manual is the obvious first step – for my IH B275 and 434 the figures are:

Converting from compression ratio to pressure isn’t simple. As the gas is compressed it heats up which also causes an increase in pressure. Just knowing the compression ratio doesn’t take into account when the valves open and close, gas speeds and several other factors. If you don’t have the figures for the engine under test you’ll either have to guess or find a similar good engine to test as a benchmark.

In reality, the compression test tends to be most useful for comparing cylinders – a good engine usually matches to within about +/-10%.

On good engines I’ve seen something of the order of 350 psi for the B275 and 450 psi for the 434 with my tester but, as there’s no calibration certificate with the tester, I don’t know how accurate its numbers are. Below about 315 psi and 405 psi respectively for these engines would tend to indicate problems.

Re-bored or re-lined engines often tend to be slightly lower compression until they’ve had chance for the rings to bed in so don’t be too surprised if the values are a little on the low side on some of the cylinders.

If compression is low on a cylinder, try adding a couple of squirts of oil from an oil can into the bore and repeat the test. If the compression has gone up then the bore is likely to be the problem, if not then head gasket or valves are the more likely culprit.

Leakdown Testing

Compression testing can indicate that there is a problem on one or more cylinders, but why? Possible causes include:

- Blown head gasket – gas is flowing between adjacent cylinders or into the water jacket

- Worn or scored bores, stuck or broken rings

- Valve not seating

- Leaks around injectors or glowplugs – this can be visually checked with some soapy water

- Cracked cylinder head

- Porous liners – these should also show problems with the radiator loosing water or even bubbles from the radiator

An alternative way to get a bit more information is to use a leakdown tester like these, again available via the internet currently for under £25.

The leakdown tester takes air from a compressor and, in this example, through its own pressure regulator with the left gauge showing that pressure.

In the aluminium block between the two gauges is restriction in the air path. The faster the air flows through the restriction, the greater the pressure drop. When its output is connected to a cylinder (in the same way as the compression tester) the flow rate will be determined by leakage in the cylinder. The leakdown test is a static test (engine not rotating) but the engine will need to be turned over to where both of the cylinder’s valves are closed.

Some people prefer this method to the compression tester. It takes a little more effort to use as one has to adjust the input pressure to get a sensible range of values on the second gauge but listening and looking for where the air goes can provide additional information:

- Air bubbling out of the radiator (cap off) – cylinder head gasket blown or porous liner

- Air out of the inlet manifold – inlet valve leaking

- Air out of the exhaust manifold – exhaust valve leaking

- Air from the rocker box breather – leakage in the bores

Conclusions

Hopefully this article has been of help and you have a better idea of the reason for the smoke and how to resolve the problem.

You may decide to just live with things - most of the time this will not cause any major issues other than for example poor starting.

The one area however that should get immediate attention is a potential leaking cylinder head gasket as I’ve seen cases where ignoring this can lead to needing a new head, liners and pistons.

© ANDREW CHAPMAN & ANGLO AGRIPARTS LTD

Licence Terms

You are free to: Share, copy & redistribute the material in original format for any purpose as long as you follow the license terms below:

- Attribution – you must give appropriate credit and provide a link to the original article in a reasonable and visible manner

- You may not in any way suggest that the licensor endorses you or your use.

- No Derivatives – The material must be distributed in full, including disclaimer, you may not distribute or share modified material.

- No additional restrictions – You may not apply legal terms that legally restrict others from doing anything the licence permits.

- No warranties are given. The license may not give you all of the permissions necessary for you intended use. For example other rights such as publicity, privacy, or moral rights may limit how you use the material.

Disclaimer

Tags engine, smoking engine, anglo agriparts, tractor