International Harvester 434 Major Works Part 5 - Timing Gears

International Harvester 434 Major Works Part 5 - Timing Gears

This article describes the inspection and overhaul of an International Harvester 434 timing gears. These are the same as fitted to all the BD154 engines (tractors B414, 434, 444, etc.), most of the BD144 engines (B250, B275, 276, etc.) differing slightly from the early B250 with the inline injector pump, but is similar enough to most makes of engines. This is therefore likely to be of more general interest.

There is a circular plate on the timing cover, behind which is the injection pump timing gear which needs to be removed before the pump. From the sludge on the gear, it should be obvious why the later photographs are taken when everything has been thoroughly cleaned!

Just visible are three bolts which hold the gear to the injection pump. There is also a dowel pin between the two lower bolts… again only just visible.

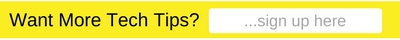

This image shows a clean set of timing gears with the main cover removed. The hydraulic pump is driven by a gear that fits through the hole just visible in the top left of the image and meshing with the camshaft gear.

The camshaft gear is a replacement. The originals are red and with three holes rather like the fuel injection pump gear.

There are timing marks on each of the gears, highlighted in this case by yellow marker pen. Actual setting of the timing will be covered in a later article when they are re-assembled.

Many engines get rebuilt without checking the timing gears for wear. However, worn gears can lead to increased engine rattle, reduced power and occasional puffs of unburnt fuel due to misfire as a consequence of injection timing variations.

These engines are very rugged and will keep running when very worn, but it isn’t too difficult to measure the wear.

The workshop manual specifies a backlash of between 2.5 and 4.5 thou. There are at least three different ways that I can see to check this in the home workshop and are described below.

All testing should be done with the cylinder head and pushrods removed. The gears should be clean/degreased. Spraying with brake cleaner is a simple way to prepare them for measurement.

Feeler Gauges

A feeler gauge is a simple and low cost way to check the backlash if it is inserted between gear teeth when they are in closest engagement. This will be when they are aligned between the centres of the two gears.

A feeler gauge is probably too wide to fit between the teeth, but the individual feelers can be cut to make them narrower. Gauges are available from the likes of Toolstation for less than £3 so this isn’t too expensive a solution.

An even cheaper source of gauge material is a piece of metal cut from a drink can. Depending on the can, the material may be steel or aluminium and these typically are 6 to 8 thou thick – check with a digital vernier or micrometer. Something of this thickness would make a simple go/no go gauge.

- If it doesn’t fit, the gears are likely to be ok

- If it just fits between the gear teeth then the backlash is enough to think about replacement.

- If two thicknesses will fit, the wear is bad and the gears are likely to be noisy and need changing.

Dial Indicators

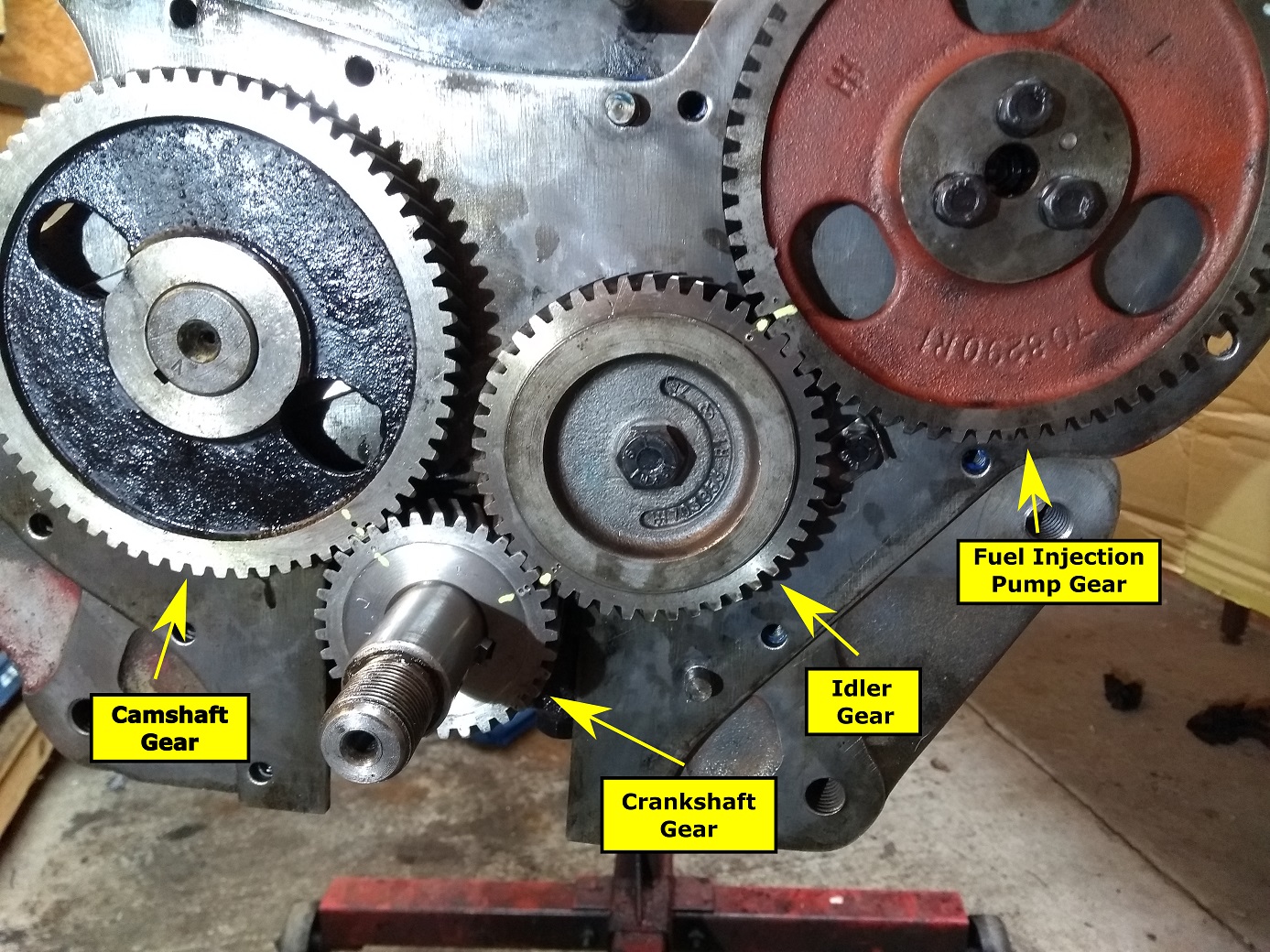

A dial test indicator or dial gauge can be set to read the movement of a gear tooth.

Finding the best place to take a measurement isn’t always that easy but this photograph shows a dial test indicator probing the edge of a gear tooth.

While ideally the measurement should be taken with the gauge acting tangentially to the gear’s circumference, the positioning shown here is close enough to get a good idea of wear.

A dial gauge can also be used. Here the gauge is measuring the camshaft gear looking through the hydraulic pump mounting hole.

This is the same gauge from the back with its probe tip just resting on the end of the gear tooth.

To check backlash, hold the mating gear still, rotate the gear being checked to one limit (i.e. as far as it will go without moving the other gear), zero the gauge and the move the gear to the other side of its free movement. The difference is the backlash.

Sensible backlash limits are likely to be:

- Within workshop manual tolerance – great.

- Less than twice the recommended tolerance – still probably ok for general use but possibly with a slight reduction in engine power levels and efficiency.

- More than twice the recommended tolerance – likely to be noisy, engine possibly starting to be rough and it would be sensible to replace if new gears are available.

By Hand

The previous methods provide an objective measurement of the backlash but, with experience, simply rocking one gear while holding the other stationary is often good enough.

- At the recommended clearance, rocking one gear against the next shouldn’t feel as if it is moving.

- Above about 5 thou, movement should be visible to the naked eye.

- Above about 10 thou, movement can be felt by hand.

The threshold for these figures will differ slightly from person to person but if you can see one gear move then it is likely to need replacing.

Which Gear is Worn?

Backlash measures the clearance between a pair of gears, so is it one, the other or both? For the home workshop swapping for a new gear is the ultimate test but sometimes an informed guess can help.

Assuming the gears were originally manufactured to the same speciation then the most obvious factors are likely to be:

- Lubrication – if a gear has poor lubrication then it is likely to have more wear. Normally lubrication is not an issue but if the idler gear’s centre had its oilway blocked that could be an issue.

- Number of Teeth – the smaller the number of teeth, the more times each carries load. The camshaft and injection pump gears rotate at half the crankshaft speed so could be expected to have half the wear. The idler gear has more teeth than the injection pump gear so is rotating slower than the crankshaft but faster than the injection pump… so wear likely to be somewhere between the two. The crankshaft gear also drives two gears so this is likely also to double its wear.

- Load – a gear with heavier load is likely to wear faster than one lightly loaded. The crankshaft gear drives everything and so will be the most heavily loaded.

So taking all these factors into account, the crankshaft gear is likely to show the most wear, possibly followed by the hydraulic pump gear (also small.) These two gears also tend to be the most readily available for this engine. To put some numbers to the wear on this engine, the specified backlash is 2.5 to 4.5 thou. Measured values were:

- Hydraulic pump -> camshaft 15 thou

- Camshaft -> crankshaft 13 thou

- Crankshaft -> idler 7.5 thou

- Idler -> injection pump 3.9 thou – the only pair in tolerance

The idler and injection pump gears weren’t changed but the other three were. Backlash on all pairs of gears was then within specification.

The next part of this series will address the camshaft.

ARTICLE CONTRIBUTED BY ANDREW CHAPMAN

© ANDREW CHAPMAN & ANGLO AGRIPARTS LTD

Licence Terms

You are free to: Share, copy & redistribute the material in original format for any purpose as long as you follow the license terms below:

- Attribution – you must give appropriate credit and provide a link to the original article in a reasonable and visible manner

- You may not in any way suggest that the licensor endorses you or your use.

- No Derivatives – The material must be distributed in full, including disclaimer, you may not distribute or share modified material.

- No additional restrictions – You may not apply legal terms that legally restrict others from doing anything the licence permits.

- No warranties are given. The license may not give you all of the permissions necessary for your intended use. For example other rights such as publicity, privacy, or moral rights may limit how you use the material.

Disclaimer

Related Articles

International Harvester 434 Major Works Part 4 - Strip, Clean & Initial Inspection

In Andrew's latest article he focusses on the stripping, cleaning and initial inspection of the various components fitted to the engine block on his International Harvester 434.