Tractor Steering Overhaul Part 4 - Steering Box

Steering Overhaul Part 4 - Steering Box

This description relates primarily to the steering boxes fitted to the Bradford built International Harvester tractors.

It is assumed that an initial assessment of the steering box has been carried out as described in part 1 of this series.

There were at least four different types of steering boxes fitted excluding anything with power steering.

1. B250 with two drop arms, one on each side of the tractor. This also uses a unique steering wheel with a large fixing nut. Information on this is not covered in this document.

2. B275 and B414. Early boxes didn’t have adjustment for rocker shaft end float. The steering wheel is located with a woodruff key on a taper and retained by a chromed domed nut and washer (A56749), all of which are the same fitting as the Ferguson T20. The steering wheel is 18” diameter so while Anglo’s A59964 will actually fit, as it is only 15” diameter, steering would be heavy.

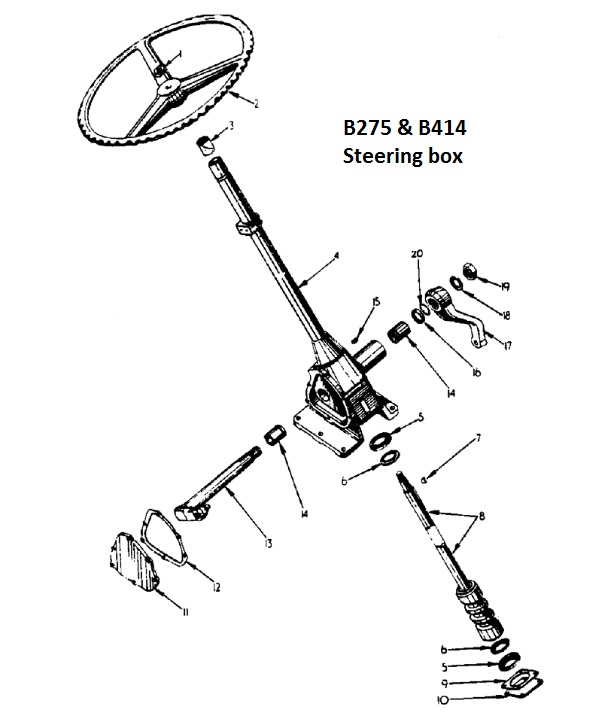

At the time of writing the Case IH online parts details show a wrong exploded parts diagram for the B414 box – the parts are correctly identified but the image is mirrored.

This correct image doesn’t show the end float adjuster which is fitted to the plate at the left of the picture (item 11) on later steering boxes

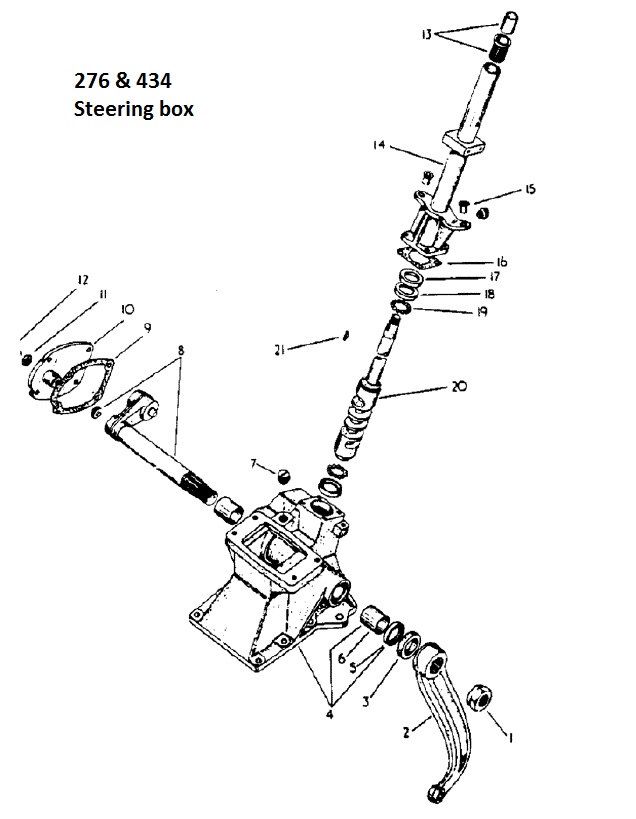

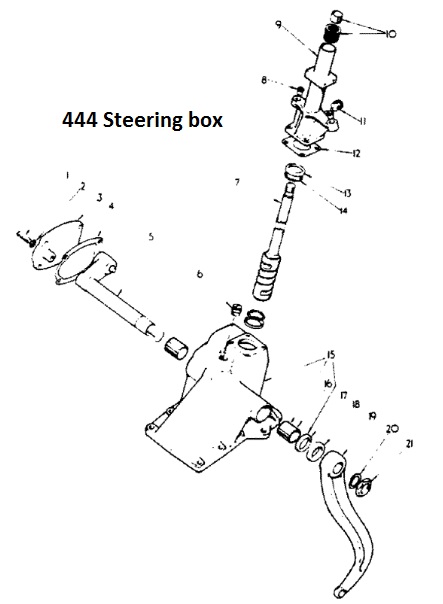

3. 276 and 434. This is a significant improvement on the B275/B414 box but isn’t interchangeable. The steering wheel is different from the B275/B414 in that it has a recess for the fixing nut and a cap with the IH logo. The earlier and more readily available steering wheel does however fit.

4. 444. The main casting of this box differs from that of the 276/434 but uses the same internal parts. Repairs to this box are therefore the same as for the 276/434. The steering wheel was again changed from previous tractors but, as it uses the same internals as the 276/434 box, the earlier steering wheel will fit.

Inside The Boxes

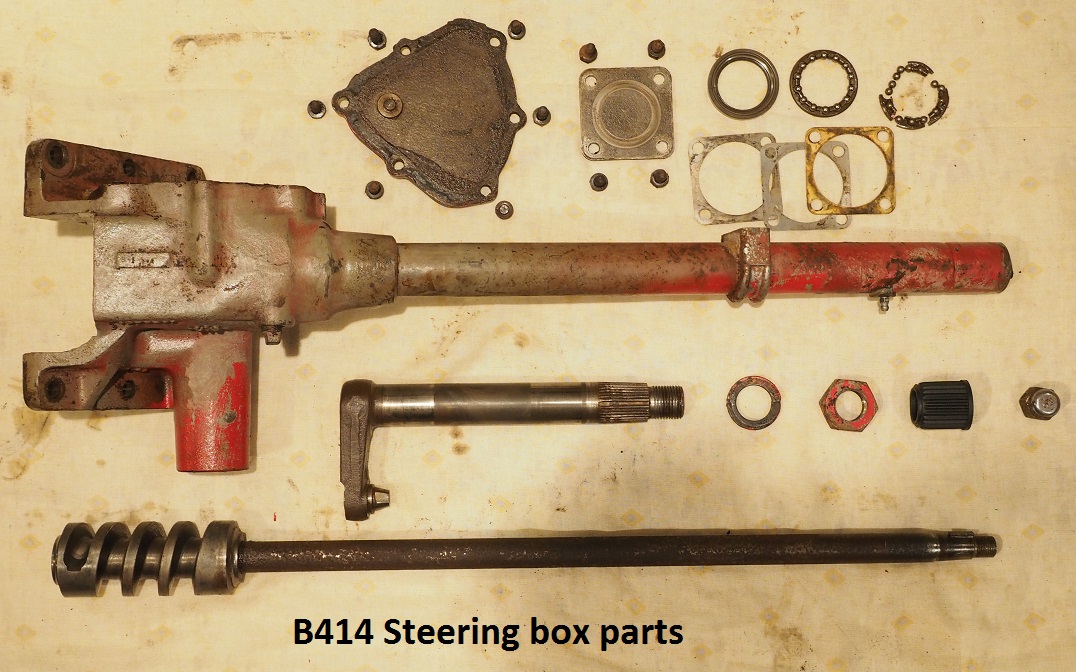

This picture shows the parts that make up the B275 and B414 steering box. The only part shared with the later boxes is the black plastic bush to the right of the picture (Anglo’s A68063) which fits in the top of the steering column. This bush can be swapped quite easily, only requiring the steering wheel to be removed first.

The plate at the top has the rocker shaft end float adjuster.

There are two thrust races that fit one above and one below the steering shaft worm. The bearings should be held in a cage, one of which had totally disintegrated in this box.

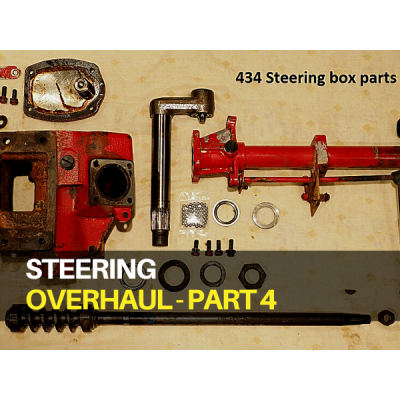

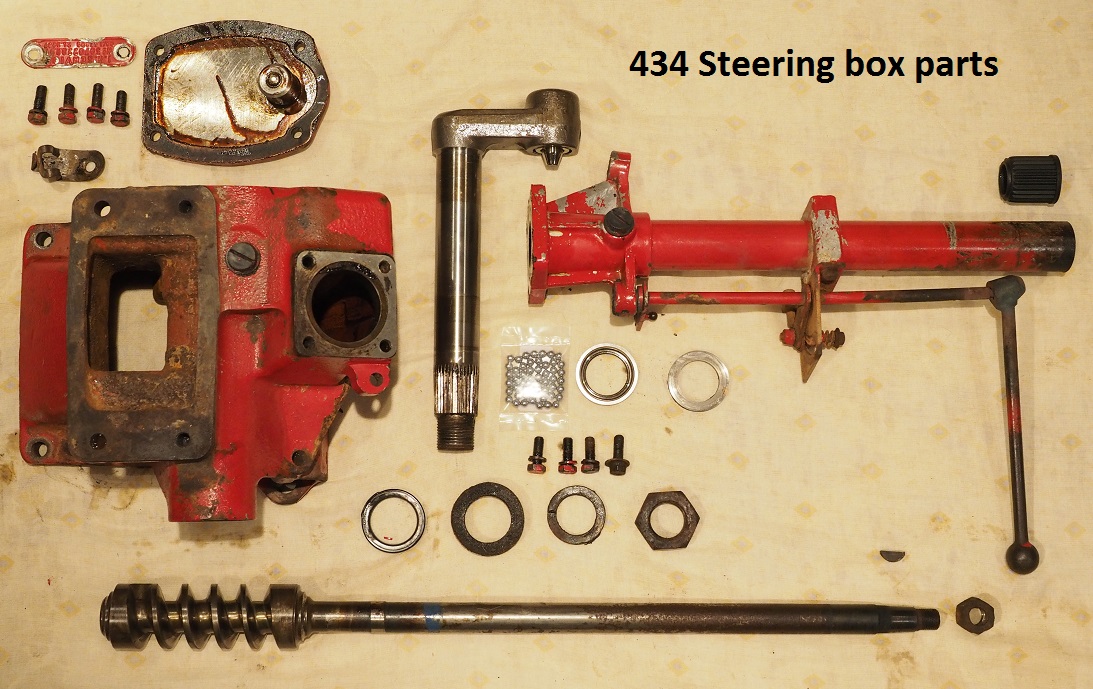

This picture shows the parts from the later 276 and 434 steering box. Compared with the earlier design, the main casting is much heavier, the column tube significantly shorter as is the steering shaft. The rocker shaft is of heavier construction and has a much improved pin as will be seen in the later photographs. The thrust bearings differ from the earlier design in that they are loose rather than held in a cage. This particular box on my 434 appears to be a service exchange unit by the label (the tag top left of the picture) but was actually missing one of the ball bearings, presumably missed when factory reconditioned.

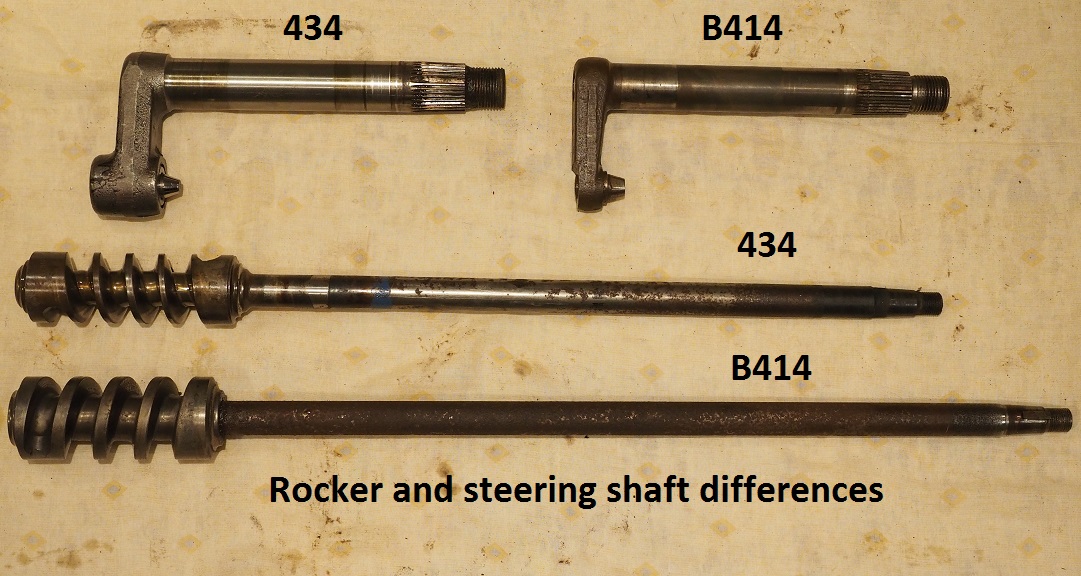

The differences in rocker and steering shafts can be better seen in this photograph.

What is also interesting is that the helix on the two steering shafts is in opposite directions.

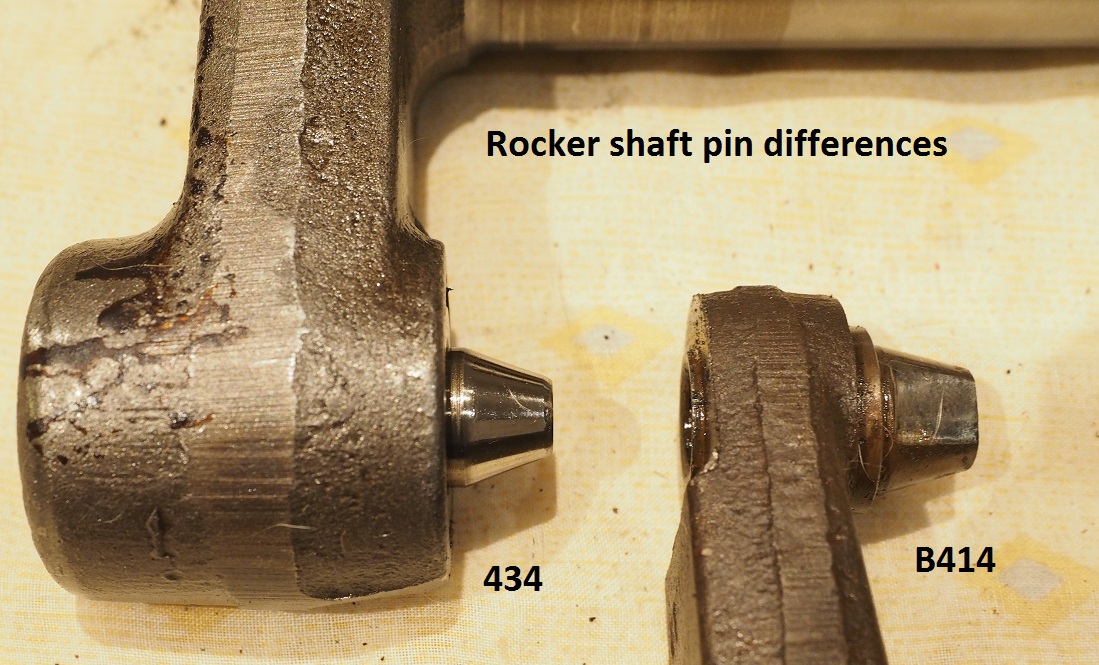

The rocker shaft pin is the main point of wear in the earlier steering box. This photograph shows how much heavier the rocker shaft is around the pin in the later design although the tip of the pin is actually smaller.

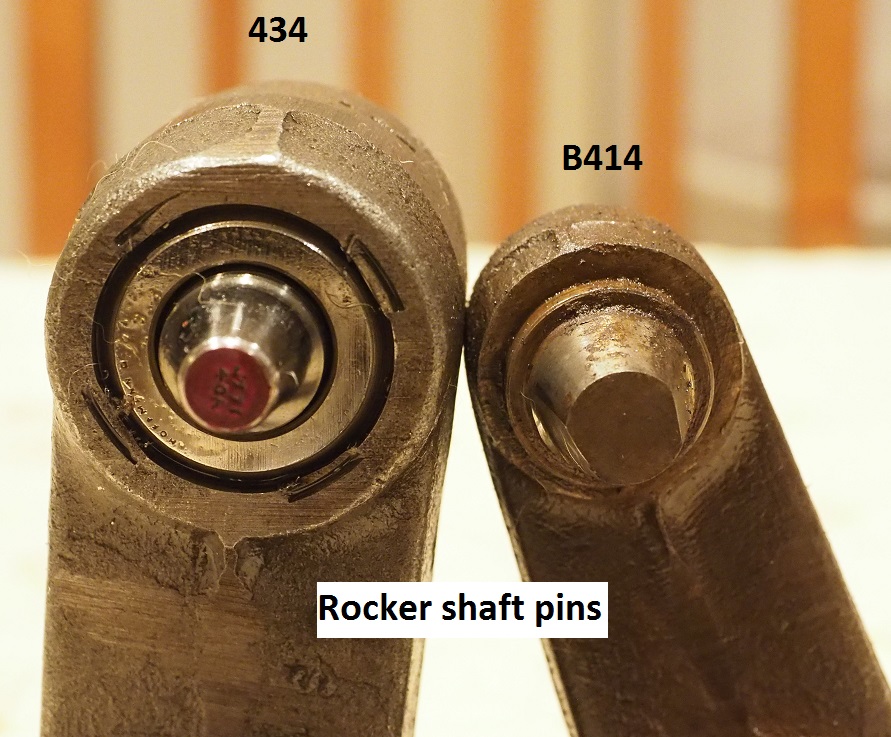

The reason for the difference is more apparent in this picture. The earlier pin is pressed into the end of the rocker shaft and wears on two fixed edges. The later pin rotates in a needle roller bearing so is much less prone to wear.

This picture shows the rocker arm pin wear that occurs in the earlier steering boxes and contributes most of the slack although other parts of the steering box play their part. The flats are easily seen on both top and bottom of the pin.

There are three possible fixes to this problem. In order of improving quality they are:

1. Build up the pin with a hard welding rod and grind back. While this can give some improvement, a freehand approach it is unlikely to give a very precise profile.

2. Press out the pin (I found it took a 30 ton press) and reinsert it rotated by 90 degrees so the non-worn surface will be used. This should give quite a lot of improvement but will still have left some wear and consequent steering slack.

3. Press out the pin and replace with a new one. The pins appear to be available in America but the only person I know of in the UK to have any is Ian Dennison (01524 751220.) This removes all the pin wear but leaves wear in the helix although in practice, based on one sample that I’ve done, this works very well.

Replacement bearings are available in kits for the B275/B414 boxes. The 276/434/444 boxes use 34 off loose standard ¼” ball bearings which are readily available from online bearing suppliers.

The bush that the rocker shaft rotates in doesn’t tend to wear that much but are available from some suppliers and is also included in some of the bearing kits.

The lip seal around the rocker shaft however does deteriorate with age and probably will need changing. The B275/B414 box uses an uncommon size and so tends to be hard to find and expensive. It is also not the easiest bush to fit – in the 50 years since I first changed a seal this is the only one I’ve ever bent! This is best installed with something to slide into the bush and a shoulder to ensure that it is pressed in uniformly - I turned up a special tool on the lathe.

The seal on the 434 however is a standard size readily available from most online bearing suppliers.

The 434 also has a foam washer between the drop arm and the steering box. This can deteriorate, replacements don’t seem to be available but it can either be discarded or something made from closed-cell plastic foam.

Final Assembly and Adjustment

Final assembly and adjustment is in two stages, firstly the steering shaft and then the rocker shaft.

Steering Shaft

The steering shaft is easy to assemble on the B275/B414 boxes as the ball bearings are caged.

The loose balls on the later boxes however can be quite difficult to assemble as they can easily fall down into the main casting. Holding them in place with grease is a major help.

The B275/B414 box has a plate at the bottom of the box that supports the lower steering shaft bearing with shims to adjust clearance. The 276/434 box has a detachable steering column with shims between it and the main casting.

Getting the correct shim adjustment here is critical to minimise play. The shims come in different thicknesses and, at least for the B275/B414 bearing kit, new shims are available. If all else fails, a drinks can is a readily available source of about 6 thou aluminium. Shim material is available in different thicknesses online as another alternative if needed.

If a dial gauge is available, check the end float when trying to move the steering shaft up and down. Alternatively, gradually reduce the thickness of shims used until the shaft starts to become stiffer – if you can’t rotate the shaft by hand then it is too tight but there should be NO end float. The workshop manual specifies < 0.001”.

Rocker Shaft

Once the steering shaft is in place and correctly shimmed, insert the rocker shaft, gasket and cover with appropriate sealant. End float is adjusted by the screw on the side plate or, in the case of the early B275, shims.

The steering boxes were initially designed to be tight at the straight ahead position and easing when moved to turn left or right. The workshop manual specifies 6-20 lb measured at the edge of the steering wheel. When rebuilding a box this tends to mean tighten the adjustment until the steering wheel starts to feel a little stiff in the straight ahead position. Straight ahead is found by counting the number of turns from lock to lock and moving to the midpoint between the limits.

Finding Spares

Top bush: Anglo Agriparts A68063 fits all models from B275 onwards.

B275/B414 steering wheel: Anglo Agriparts A59964, This also fits the B276/434 and 444 but not original style.

B275/B414 bearings and seals: Anglo Agriparts A91180 steering box seal kit includes the top bush, bearings, rocker shaft bush & seal, woodruff key and shims – basically everything except a replacement rocker shaft pin. The lip seal is 1-1/4”” ID, 1-1/2” OD and 1/4” width.

B275/B414 rocker shaft pin: Ian Dennison (01524 751220.)

B276/434/444 bearing: 34 off 1/4” loose ball bearings, Anglo Agriparts A91182

B276/434/444 rocker shaft seal: The lip seal is 1-3/8” ID, 1-7/8” OD and ¼” width, available from Simply Bearings, Bearing Boys or Bearing King

ARTICLE CONTRIBUTED BY ANDREW CHAPMAN

© ANDREW CHAPMAN & ANGLO AGRIPARTS LTD

Licence Terms

You are free to: Share, copy & redistribute the material in original format for any purpose as long as you follow the license terms below:

- Attribution – you must give appropriate credit and provide a link to the original article in a reasonable and visible manner

- You may not in any way suggest that the licensor endorses you or your use.

- No Derivatives – The material must be distributed in full, including disclaimer, you may not distribute or share modified material.

- No additional restrictions – You may not apply legal terms that legally restrict others from doing anything the licence permits.

- No warranties are given. The license may not give you all of the permissions necessary for your intended use. For example other rights such as publicity, privacy, or moral rights may limit how you use the material.

Disclaimer

Related Articles

Tractor Steering Evaluation

Contributor Andrew Chapman carries out a steering evaluation referencing IH Bradford built tractors.

Tractor Steering Overhaul Part 1

Contributor Andrew Chapman compares the various methods for splitting swivel joints on steering overhauls.

Tractor Steering Overhaul Part 2

Part 2 of Andrew Chapman's steering overhaul review. This article is based on rebuilding the steering knuckles and hubs on Bradford built International Harvester B275, B414 and 434 tractors.

Tractor Steering Overhaul Part 3

This

article is based on rebuilding the front axle pivot pin and bushes on Bradford

built International Harvester B275, B414 and 434 tractors. The design of the

parts are however similar to those on many tractors of the period and so should

be of general use

Ferguson TED20 - Removing The Steering Box - Video Tutorial

The steering box contains the gears that transmit the driver's steering movements to the steering linkage that turns the wheels. In this video Gordon investigates steering issues on his TED20 - part 1 follows the step-by-step removal of the steering box.

Ferguson TED20 - Assembling Steering Box - Video Tutorial

Watch Gordon's latest installment in his video series restoring a Ferguson TED20.